What We Do

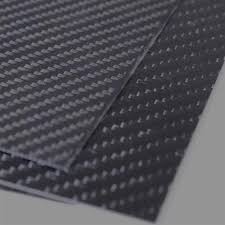

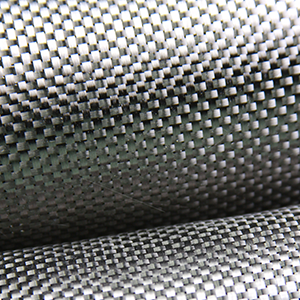

We are a Research & Development company specializing in material sciences applying our Differential Pressure Assisted Resin Transfer (DPART) fabrication process to enable next generation efficiencies with carbon fiber manufactured parts.

For Commercial & Military Aerospace products our DPART process is making industry compatible aerospace parts, using the same materials and resins that are 30% stronger than industry standard VARTM produced parts. Stronger means lighter, as we require less material. Less material means cheaper. Lighter means extended ranges to UAV & Drone markets.

We have a 30% pricing advantage in an annual $40 Billion replacement and retrofit marketplace.

Instaclave Technologies is the primary licensing source for the DPART process in Aerospace, Automotive, Medical and Manufacturing sectors.

Our Target Research & Development Markets

Instaclave Aviation™

Opportunities in Aerospace are available now. Open for business. Our DPART fabrication process for Military and Commercial Aircraft upgrades and replacement components are a $40 billion opportunity.

Instaclave Aerospace™

Our Inflatable Carbon Fiber research project unlocks opportunities in Aerospace and Space Systems Using the DPART process. Fabrication of large to massive structures, compliant with NASA standards. Visualize Space Stations with gravity!

Instaclave Medical™

Utilizing the the DPART process in the micro scale, mechanical replacement parts are more sterile and easier to apply and much more cost effective. Our Inflatable Carbon Fiber technology will allow large elements to simply inserted via a small tube.

Instaclave Automotive™

The fabrication of production line components are much more cost effective using our Inflatable Carbon Fiber and DPART process. Rapidly form structural modules in minutes. No steel production, no fabrication, no transport cost.

Instaclave Energy™

Opportunities in Energy are vast using our Inflatable Carbon Fiber & DPART" process. Fabrication of large scale drilling and routing systems are possible. Imagine drilling and placing piping simultaneously.

Instaclave Construction™

Utilizing the our Inflatable Carbon Fiber & DPART" process in the commercial construction scale. Self-deploying and on-site fabrication. Think of prefab I-beams in a box!

Instaclave Engineering™

Designing, fabricating and installing these systems in the field is a full time career in itself. These are high quality engineering and technician jobs.

Check our Jobs Board page for more details.

Instaclave Chemicals™

Opportunities using the DPART process. Fabrication and application of composite resins are available, custom designed to each client application. Licensing is also available for manufacturing DPART compatible resin and binders.

Instaclave Materials™

Opportunities using the DPART process. Fabrication of composite materials are available, custom fabricated to each client application. Licensing is also available for manufacturing DPART compatible materials.

Instaclave STEM Support

Supporting Middle School, High School and College Design, Science, Technology, Engineering and Math programs, to inspire young engineers. To promote our Design tools and processes for the next generation of innovative design professionals.

Request STEM Information